Working with a polarization filter: Essential in modern production processes

Reflections, white spots, and unreadable labels – anyone working in production has undoubtedly encountered these challenges. Especially at high speeds and with complex packaging, correctly scanning data such as barcodes or labels can be difficult. This is where the power of a polarization filter comes into play.

This smart tool prevents disruptive reflections and ensures a stable and accurate reading process, even in the most demanding conditions.

In this blog, we explain what a polarization filter is, how it works, and why it is essential for companies with a production department. Whether you work in the food industry, pharmaceutical sector, or logistics, this article provides practical insights to improve your production processes.

What is a polarization filter?

A polarization filter is an optical tool used to minimize reflections and glare. The filter controls how light is reflected and captured by a camera system. This is especially useful in situations where products have reflective surfaces, such as glossy packaging, plastic, or metal labels.

When scanning labels or other visual data in a production environment, lighting can often reflect off the product’s surface. This leads to white spots or distortions in the image, making data difficult to read. A polarization filter solves this problem by:

- Directing the light from the illumination at a specific angle.

- Capturing only the reflected light at a different angle through the lens.

The result?

Stable, reflection-free images that are consistently and accurately read.

How does a polarization filter work?

The concept behind a polarization filter sounds more complex than it is. Here’s how it works in a production environment:

- Directed light emission: The system’s lighting is adjusted with a polarization filter that emits light at a specific angle. This prevents light from reflecting straight off the surface and back into the lens.

- Filtered light capture: The cameras in the system are equipped with a polarization filter that only captures light entering at a specific angle. This filters out reflections and glare from the image.

- Accurate reading: With less distortion in the image, the camera software can effortlessly and accurately read labels, barcodes, and other visual data.

Real-world example: A customer producing soft drink bottles frequently faced reflections on glossy labels under bright production line lighting. As a result, barcodes were not always read correctly, causing delays. By adding a polarization filter, reflections were completely eliminated, and the line ran smoothly without errors.

Benefits of a polarization filter

Using a polarization filter offers a wide range of advantages for companies with a production department:

- Improved reading accuracy: Labels and barcodes are read much more accurately, even on glossy surfaces.

- Stable performance at high speeds: In fast production lines, stability is crucial. Polarization filters minimize disruptions, preventing delays.

- Cost savings: Fewer errors mean less rework and waste. Additionally, a polarization filter extends the lifespan of your camera system by ensuring consistent performance.

- Flexibility: Whether working with plastic, glass, metal, or another reflective material, a polarization filter adapts and delivers reliable results.

- Professional end result: A reflection-free image not only looks better but also conveys professionalism to customers and partners.

Practical applications

Polarization filters are widely applicable and can make a difference in various sectors:

- Packaging industry: Reading barcodes on glossy packaging, such as candy wrappers or beverage bottles.

- Food industry: Quality control on labels or detecting defective packaging.

- Pharmaceutical sector: Reading serial numbers and batch codes on medications, where accuracy is crucial.

- Logistics: Scanning labels on boxes or pallets in a warehouse environment.

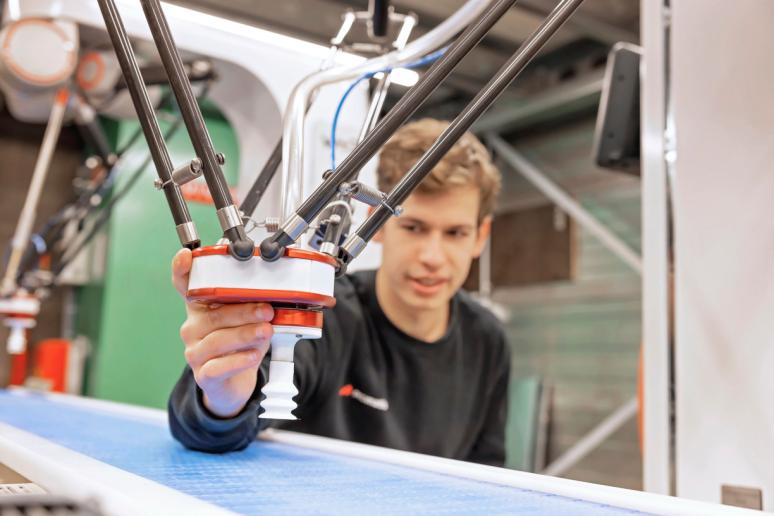

Polarization filters and vision systems from Promation

At Promation, we understand the importance of optimizing vision systems. That’s why we use Cognex cameras combined with high-quality polarization filters. These systems are specifically designed to tackle the challenges of modern production environments.

Why choose Promation?

- Customized solutions: Every system is tailored to your specific needs.

- Efficiency: Our vision systems are optimized for speed and accuracy.

- Expertise: As specialists in automation, we have years of experience in implementing smart solutions.

Practical example: A customer in the cosmetics industry struggled with reading codes on glossy perfume bottles. Thanks to our vision systems with polarization filters, reading accuracy improved from 80% to 99.9%, leading to significant improvements in their logistics processes.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Polarization filters make the difference

Working with a polarization filter is a simple yet effective way to enhance the performance of your production processes. By eliminating reflections and glare, you not only improve accuracy but also the speed and reliability of your systems.