Why choose a machine retrofit?

The choice between a retrofit and a new machine often seems straightforward: a new machine sounds modern, efficient, and hassle-free. However, many companies consciously opt for a retrofit—and for good reason. Adapting and upgrading an existing machine can be a smart move, both financially and operationally.

As specialists in industrial automation, we have years of experience performing retrofits. In this article, we outline all the pros and cons to help you make an informed decision.

What is a retrofit?

A retrofit means upgrading or modifying an existing machine to bring it up to date. This could involve:

- Replacing the control system.

- Adding new functionalities.

- Integrating modern technologies such as cobots or vision systems.

The goal: Extend the machine’s lifespan while making it more efficient, reliable, and modern.

Why opt for a retrofit?

It’s cheaper than a new machine

Buying a new machine is a significant investment. With a retrofit, you retain the mechanical base of your existing machine, which is often still in excellent condition. This allows you to save substantially on costs.

Example:

A client had a packaging machine whose mechanical components were still in perfect working order, but the control system was outdated and unreliable. By integrating a new Siemens control system, the machine became fully operational again at a fraction of the cost of a new installation.

Older machines are often mechanically stronger

Many older machines were built as robust workhorses. While the mechanical parts can last for decades, the control systems become outdated or unsupported. A retrofit allows you to preserve the strong mechanical base while adding modern technology.

Completely custom: You decide how the machine operates

A retrofit gives you the opportunity to tailor the machine exactly to your production process. You can add new functionalities, integrate specific options, and optimize its operation. This is a significant advantage over standard machines, where you have less influence on the configuration.

Example:

A client wanted a machine that could not only fill boxes but also stack them automatically. During the retrofit, we added a cobot, making the machine far more efficient than any standard solution.

Preserving unique applications

Some machines have unique functionalities or dimensions that are hard to replace. A retrofit is the perfect way to make these machines like new again without losing functionality.

Are there drawbacks to a retrofit?

Temporary downtime of the machine

During a retrofit, your machine will need to be taken out of production, which can impact your production planning. Depending on the scope, this downtime can last weeks or even months.

When to choose a new machine?

If you cannot afford extended downtime, a new machine is often a better choice. A new machine can be replaced directly without significantly disrupting your current production process.

No direct replacement like with a new machine

A new machine is typically delivered as a complete package and can be quickly implemented in the production line. With a retrofit, you work with the existing base, meaning you remain dependent on the original machine.

While retrofits offer many benefits, there are situations where a new machine is the better choice:

- If the mechanical parts of your current machine are worn out.

- If your production volume needs to increase significantly and your current machine cannot keep up.

- If speed is essential and you cannot afford long downtime.

Retrofit at Promation: What can we do for you?

At Promation, we specialize in delivering tailored retrofits. Here’s what we can do for your machine:

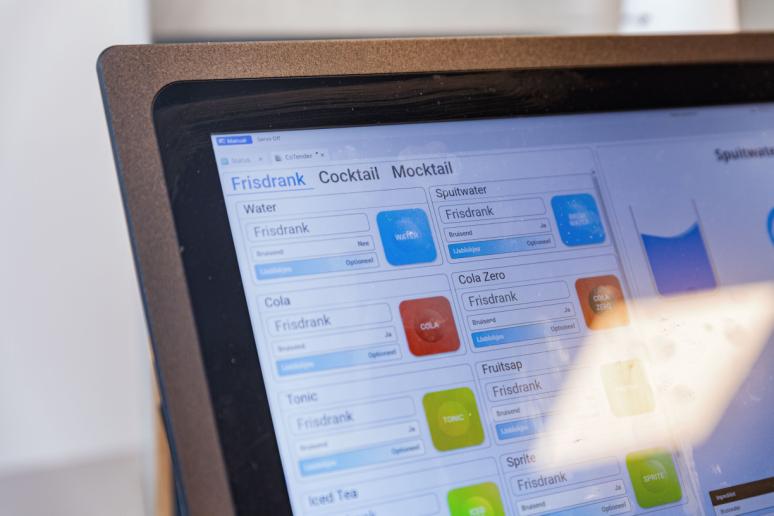

- New Control Systems: We primarily work with Siemens PLCs, the market leader in flexibility and reliability.

- Cobot Integration: Add collaborative robots like the Costacker, Cofeeder, or Cofiller to make your production process more efficient.

- Vision Systems: Use Cognex cameras for quality control, product localization, and more.

- Additional Functionalities: Adjust your machine’s operation entirely to your specific production needs.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Retrofit or new machine?

A retrofit is often a smart choice. However, sometimes a new machine is the better solution, for instance, when speed is crucial or when your existing machine no longer meets technical requirements.

At Promation, we’re happy to help you make the right choice. With our expertise in automation and custom solutions, we provide options that optimize your production process.