Which types of robots are suitable for your production process?

As specialists in automation, we at Promation witness firsthand how robots are revolutionizing production processes. However, there are many misconceptions about robots, such as the idea that they are all the same or that they pose a significant risk to employees.

In this blog, we aim to debunk these myths and provide insight into the different types of robots, their advantages, and how they contribute to efficient production processes.

What are industrial robots?

Industrial robots are powerful machines commonly used to perform heavy and repetitive tasks. They are designed for high speed and precision and are often capable of lifting heavy loads. Within this category, we distinguish two main types:

Type 1: 6-axis industrial robots

These versatile robots can move in all directions, making them ideal for complex tasks such as welding, assembly, and material handling. A 6-axis robot, for example, can perform operations like packaging products into boxes. Due to their flexibility, these robots are widely used across various industries, from automotive to food production.

Type 2: 4-axis industrial robots

These robots are less flexible than their 6-axis counterparts but excel in specific applications such as palletizing. The flange of a 4-axis robot always remains perpendicular to the ground, reducing energy consumption and allowing it to handle heavier loads. Imagine needing to stack pallets with 50 kg bags of sugar— a 4-axis robot is the perfect choice for this task.

Advantages of industrial robots:

- High speed and power

- Suitable for heavy loads

- Wide range of applications

Disadvantages of industrial robots:

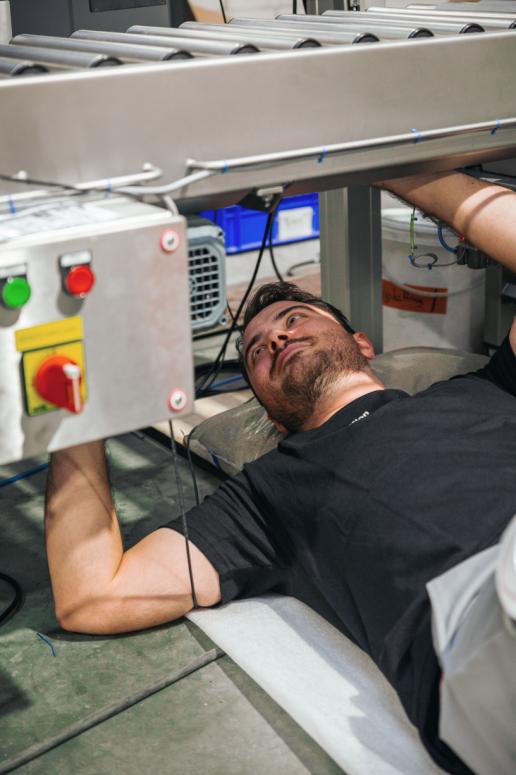

- Require safety fencing

- Regular maintenance needed, such as oil and battery replacement

Discover four types of robots for your production process

SCARA robots: the speed champions

SCARA stands for Selective Compliance Assembly Robot Arm. These compact robots are incredibly fast and ideal for light tasks requiring precision, such as picking and placing small components. Think of electronics assembly or filling medicine boxes. Due to their speed and accuracy, SCARA robots are often used in cleanrooms and production environments where every second counts.

Advantages of SCARA robots:

- Extremely fast

- Ideal for small and precise tasks

- Compact design

Disadvantages of SCARA robots:

- Limited versatility

- Not suitable for heavy loads

DELTA robots: the ultimate in speed

If speed is even more critical, DELTA robots are the better choice. These robots have three arms that work together to move the flange at lightning speed. They are often used in the food industry, for example, to package cookies or place candies into boxes. A significant advantage of DELTA robots is that their arms are often made of carbon fiber, making them extremely lightweight and fast.

Advantages of DELTA robots:

- Unparalleled speed

- Perfect for light and fast pick-and-place tasks

Disadvantages of DELTA robots:

- Not suitable for heavy loads

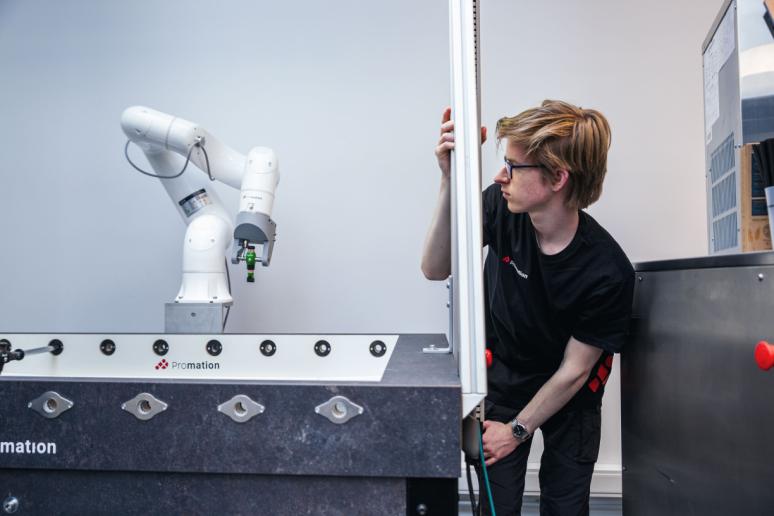

Cobots: the collaborative powerhouses

Cobots, or collaborative robots, are specifically designed to work alongside humans. They have built-in sensors that detect obstacles in their path, automatically stopping to prevent accidents. This makes them ideal for applications where safety and flexibility are paramount.

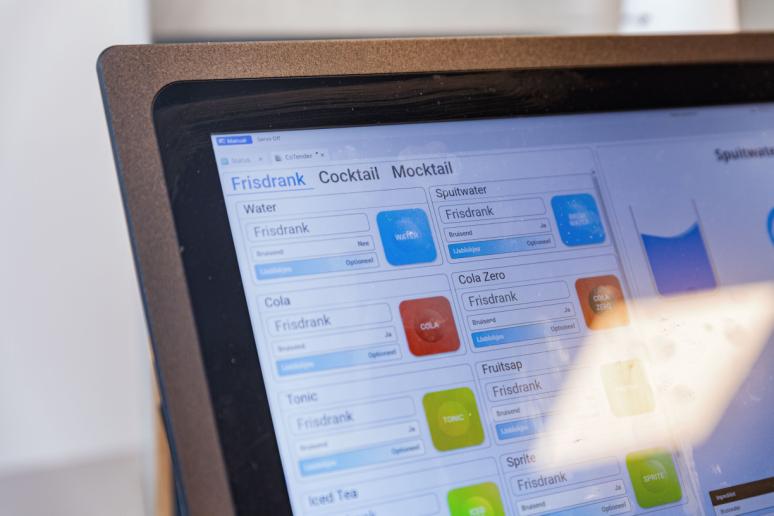

At Promation, we take pride in our in-house Cobot solutions, including the Costacker, Cofeeder, and Cofiller:

- Costacker: Stacks boxes safely and efficiently on pallets without requiring a safety fence.

- Cofeeder: Ensures a continuous supply of materials, such as cardboard or plastic parts, keeping the production process running smoothly.

- Cofiller: A filling machine that accurately and efficiently fills packaging, ideal for food products such as meals, beverages, and snacks.

Advantages of cobots:

- Safe collaboration with humans

- Low maintenance

- Flexible and easy to relocate

Disadvantages of cobots:

- Less suitable for heavy tasks (maximum capacity of 30 kg)

- Limited speed compared to industrial robots

Gantry robots: the linear workhorses

Gantry robots operate on a system of axes, bearings, and belts that enable linear movements. They are often used in large production lines, for example, to transport heavy products over long distances. While gantry robots are powerful, they require regular maintenance to prevent wear on the bearings and belts.

Advantages of gantry robots:

- Suitable for large and heavy applications

- Versatile in linear movements

Disadvantages of gantry robots:

- Requires regular maintenance

- Less flexible than other robots

Which robot is right for your production?

The choice of robot depends entirely on your specific needs. Do you need to move heavy loads at high speed? Then opt for a 4- or 6-axis industrial robot. Do you need to move small products quickly and accurately? Consider a SCARA or DELTA robot. If safety and human collaboration are a priority, a cobot is the best choice.

At Promation, we assist companies in selecting the right solution. Our ROI configurator on the website makes it easy to calculate which robot fits your production process, what the costs are, and when your investment will be recouped.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Optimize your production with Promation robots

Each robot has its own advantages and limitations and selecting the right one can significantly impact the efficiency of your production process. At Promation, we have the expertise and experience to guide you in making this decision. Whether it’s industrial automation, Cobots, or vision systems – we have the solution tailored to your needs.