What is the payback period for automation in your production process?

Companies are always looking to improve efficiency. An efficient production process means higher margins on your products. And making your production more efficient starts with automation.

Automating production lines with robots is a crucial step for many businesses toward a more efficient future. However, the lingering question often is: “Is the investment worth it?” This is a question we frequently encounter, and one we answer effectively with concrete examples.

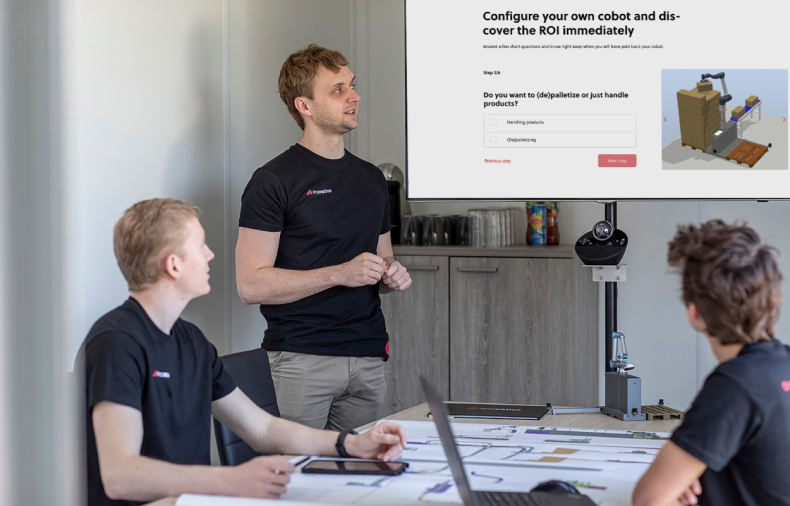

In this blog post, we will explore the cost-benefit analysis of robotic automation. And yes, we even have a dedicated ROI configurator to help.

How much does an automated production process cost?

Let’s start with the question most entrepreneurs are concerned about: What does it cost to integrate a robot into your production process?

The costs of a basic robotic installation start at approximately €70,000 and can go up to €100,000, depending on the required specifications and additional equipment, such as conveyor belts or sensors.

Example Costs and ROI of a cobot

Contrary to what many businesses believe, this investment can be recovered quickly. Let’s take our Costacker as an example. This is a cobot palletizer, costing less than €100,000, capable of up to 8 picks per minute. It is perfect for efficiently stacking boxes and packaging on pallets.

Depending on your production schedule: If you operate in 24/7 shifts, this installation can be fully paid off within 9 months. If you operate day shifts only, the payback period is around two years.

Payback period for a robotic installation

Now that we understand the costs of automation, let’s examine the payback period of a robotic installation. Imagine purchasing a Costacker setup for €100,000.

This cobot is designed for palletizing boxes. With a speed of up to 8 picks per minute, it can stack far more boxes per hour than a human. And since this cobot can work day and night, its return on investment is significant.

How quickly can you recoup your investment?

In 24/7 shift operations: your €100,000 investment is recovered in under a year. A day shift operations only: The payback period is approximately two years. This cobot not only takes over the heavy and repetitive tasks of stacking, but it also ensures consistent quality and significantly boosts productivity.

Once your investment is paid off, the real savings begin. A robot like the Costacker has a long lifespan and requires minimal maintenance. After the payback period:

- You immediately reduce labor costs.

- You sustainably increase productivity.

- You maintain optimal production quality.

The costs of manual labor

When evaluating the costs of automation, it’s essential to compare them to the costs of manual labor. In Belgium, an employee costs on average €50,000 per year, including salary, social charges, and other associated expenses like sick leave and vacation days.

In contrast, a robot can work 24 hours a day, 7 days a week, without breaks or overtime costs.

In today’s tight labor market, where finding qualified staff is increasingly challenging, automation is not just an opportunity to save money—it’s a necessity to maintain production.

Automating to stay competitive

As discussed in another blog post, robotic automation isn’t just about cost savings. It’s about survival in an increasingly demanding market. In Belgium, the labor market faces a significant shortage of workers, and more and more companies struggle to find enough staff to keep their production lines running.

More than ROI: Additional benefits

While the quick payback on robots is attractive, it is important to also look at the broader value of automation. Robots ensure consistency, reduce the risk of errors and can help improve product quality.

They also contribute to a healthier work environment by taking over repetitive, heavy or dangerous tasks.

Automation not only helps companies save on personnel costs, it also increases productivity, improves safety and increases customer satisfaction. Reducing the number of human errors means less waste and therefore less cost for repair or corrections.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Automation pays for itself quickly

The upfront costs of robotic automation may seem high, but the reality is that this investment is quickly recouped. Whether you operate in shifts or only during the day, a robot like the Costacker can pay for itself in 9 months to two years.

At Promation, we have the expertise to help businesses optimize their production processes with tailor-made automation solutions.

Want to know which robot best suits your production needs?