Will robots replace humans in production?

Automation, robots, AI. Will humans still be needed in the future? Of course, they will. There's often the misconception that robots make human jobs redundant, but at Promation, we see things differently.

Robots are essential to keeping businesses running, especially in today’s tight labor market. Data from Acerta shows that in the first half of 2023, 6.6% more employees left their jobs in Belgium than started new ones. This highlights the growing staff shortage and makes it clear that companies can no longer operate in traditional ways.

In this blog, we share our vision of the future.

The real challenge: employee turnover

The labor market in Belgium is struggling with a structural shortage of workers. With the outflow of experienced employees and fewer new workers entering the market, it’s becoming increasingly difficult for production companies to keep their processes running.

Especially in sectors like production, where physical labor and repetitive tasks are key, there’s a gap that’s hard to fill. According to Acerta, more people are leaving the workforce than joining, which means companies must look for other solutions.

More Leaving Than Joining

In the first half of 2023, 6.6% more employees left their jobs than new ones were hired. In particular, there’s a significant outflow in the age group between 30 and 50 years, which is hard to replace with new staff.

This shortage of personnel makes it necessary to automate production processes, especially if companies want to remain competitive and keep production in Belgium. Automation is therefore not a threat to jobs but an essential solution to keep production processes running.

Robots fill job gaps

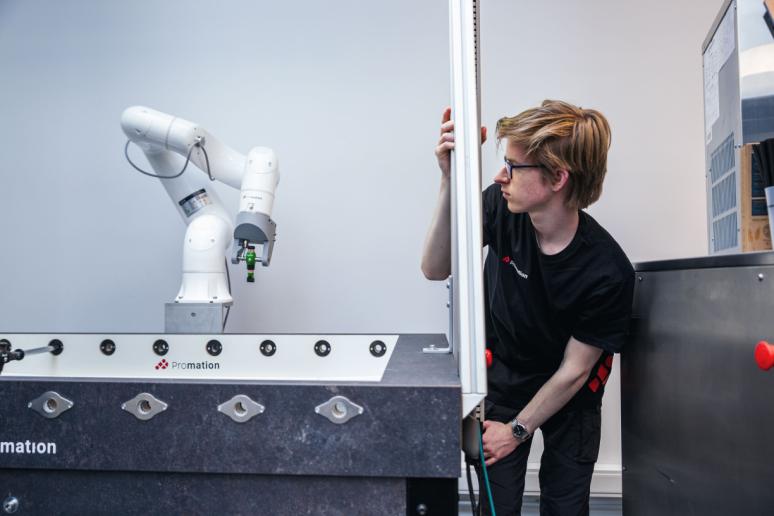

Robots don’t take jobs away; they fill the open positions that companies simply can’t fill with staff anymore. We see daily how robots like the Costacker or Cofeeder take over tasks that used to be done by people but now face a shortage of workers.

Think of tasks like stacking boxes on pallets or filling packaging. These are essential jobs, but due to the staff shortage, it’s often hard to find enough employees to fill these roles.

Not replacing, but collaborating

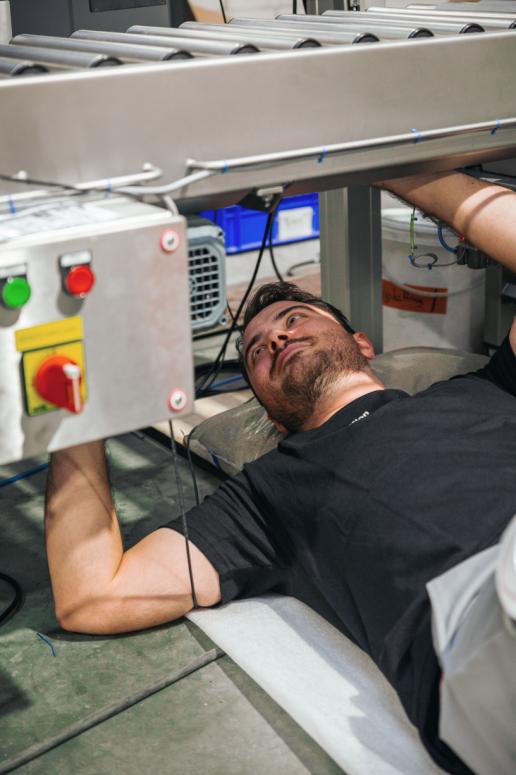

Instead of full replacement, we see in practice that robots and people work together. Robots take over repetitive, physically demanding, and monotonous tasks, while people can focus on more complex work that requires creativity and problem-solving skills.

A good example is our Costacker, which automatically stacks boxes. This used to be a labor-intensive task, but now a cobot can perform the work safely and efficiently, while employees monitor and manage the process.

Even a smart camera can help

The use of vision systems, like our Cognex solutions, also shows how automation complements human efforts. Vision systems check printed codes on packaging or inspect products for quality, which used to be manual and time-consuming. But this doesn’t mean the human factor disappears. On the contrary, people are still needed to manage the machines and quickly resolve any issues.

Automation: essential for the future

Here, we’re focusing on Belgian data, but it’s the same in other countries. The outflow of workers continues to increase, and the influx of new workers is stagnating. Clearly, this is not an ideal situation.

In such a tight labor market, it’s becoming increasingly difficult for companies to find enough qualified workers to support production. Companies that don’t invest in robots risk not being able to meet demand and may have to slow down or stop production.

Robots and automation solutions, like those from Promation, ensure that companies continue to produce, even when there aren’t enough workers available.

The solution to this problem doesn’t lie in replacing people but in combining the power of automation with the creativity of human workers. This allows companies to work more efficiently, increase productivity, and support their staff simultaneously.

Discover 10 reasons why it's best to start your automation today!

Robots and people working together: benefits

In addition to addressing the staff shortage, robotization also offers long-term benefits for companies. Robots make fewer mistakes, can work 24/7 without breaks, and improve the quality of the production process.

This leads not only to higher productivity but also to lower long-term costs. Companies that invest in robots often find that they recoup their investment within a few years, especially in sectors where staff shortages are the biggest challenge.

Calculate your ROI

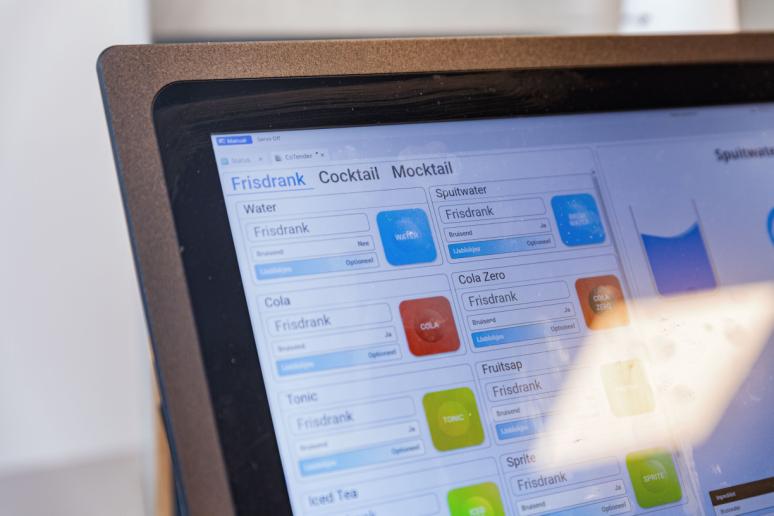

At Promation, for example, we have the Cofiller, a filling robot that can quickly and accurately fill packages. This significantly boosts production efficiency by minimizing human errors and allowing continuous operation. You can calculate the ROI of your robots here.

In the future robots and humans will be working together

Automation is not the end of work but a new way of collaborating between people and machines. In the future, we’ll see more robots taking over routine and repetitive tasks, while humans focus on tasks requiring creativity, flexibility, and innovation.

This means that companies will not only keep running but also gain a competitive advantage by working more efficiently.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Robots keep production companies running

So, robots are a crucial solution to the challenges the production sector faces, such as the growing staff shortage. They don’t replace people but fill in the gaps and ensure that production processes keep running.

Want to learn more about how automation and robots can help your production company deal with the staff shortage?

Contact Promation today and discover how our automation solutions can make your production process more efficient and flexible.