Standard delta robot and collaborative delta robot: the difference

If you work in the manufacturing industry, you’ve probably heard of a delta robot. These robots are used for ultra-fast pick-and-place tasks and are essential in sectors such as the food industry, pharmaceuticals, and electronics.

But the industrial world is changing, and collaborative delta robots are on the rise. Does this mean standard delta robots are becoming obsolete? Or are collaborative deltas just a passing trend?

In this blog, we take a closer look at both variants and help you make the right choice for your production process.

What is a delta robot?

A delta robot is an industrial robot with a unique parallelogram structure that allows it to move extremely quickly and precisely. These robots are often used for pick-and-place tasks because they can move products with high speed and precision. Their characteristic three-arm design allows them to move with minimal mass, making them faster than traditional robotic arms.

The standard delta robot has been a staple in the automation industry for years, but recently the collaborative delta robot has emerged. Let’s look at the key differences.

The difference between a standard delta robot and a collaborative delta robot

The main differences between these two types lie in speed, flexibility, and safety. Below, we’ve compared the key features:

| Standard delta robot | Collaborative delta robot | |

| Speed | 100+ items per minute | 90 items per minute |

| Safety | Requires an enclosed safety cell | Can work safely near humans |

| Mobility | No, fixed in one place | Yes, easily movable |

| Available variants | Many (stainless steel, extra axes, hygienic models, etc.) | Limited, only one variant currently available |

| Automation level | High speed and precision, but no human collaboration | Flexible collaboration with workers |

When should you choose a standard delta robot?

A standard delta robot is the best choice if:

- You need maximum speed. These robots can achieve more than 100 cycles per minute, and with optimized grippers, they can work even faster.

- You operate in a sterile environment. Stainless steel models can be fully washed down and meet the strictest hygiene standards.

- Your process is repetitive and not flexible. For example, in cookie packaging, where the robot performs the exact same task every day.

- There are no people working in the immediate area. Standard delta robots require a safety enclosure and stop automatically if someone enters the workspace.

Example: A food company sorting 150 cookies per minute into packages chooses a standard delta robot because speed and hygiene are top priorities. The work environment is fully enclosed, and the tasks are repetitive.

When should you choose a collaborative delta robot?

A collaborative delta robot (Wyzo) is ideal if:

- You want to work alongside people. These robots can work safely next to employees, without the need for safety fences.

- You need flexibility. They can be easily moved and used for different tasks within production.

- You want to build a mobile robot fleet. Thanks to their simplicity and safe operation, you can deploy multiple collaborative delta robots across different locations.

- You want a low initial investment. They require less fixed infrastructure, such as safety enclosures, which simplifies implementation.

Example: A company assembling medical kits and manually placing products into trays can benefit from a collaborative delta robot. Employees work alongside the robot without needing a safety cell, increasing productivity without losing flexibility.

A contradictory choice: collaborative doesn’t always mean better

Many companies assume collaborative robots are always the better choice because they are safer and more flexible. But that’s not always the case. In many situations, a standard delta robot is more efficient. For example, some collaborative delta robots are slightly slower and have less powerful grippers compared to their traditional counterparts.

So collaborative robots aren’t automatically better than their non-collaborative counterparts. It all depends on the application. Carefully consider your production environment before making your decision.

Request a free consultation or try our ROI configurator to see which robot will deliver the fastest return on investment!

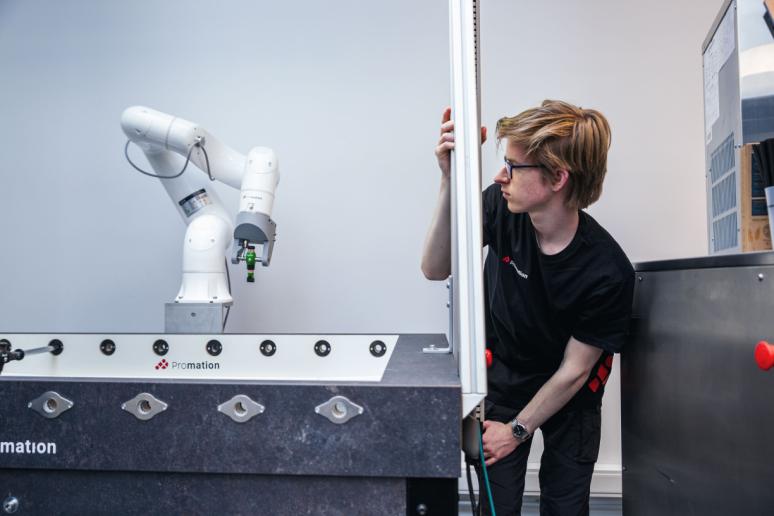

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

What’s the right choice for your business?

There’s no single answer to the question of which delta robot is better. It depends on your specific needs:

- Do you want maximum speed and precision? Choose a standard delta robot.

- Do you want to work alongside people and need flexibility? Then a collaborative delta robot is the best choice.

At Promation, we’re happy to help you make the right choice. We’re experts in automation and work with both standard and collaborative robots.