How fast is a cobot?

Since you're reading this blog, you've probably already heard of cobots. You're interested in knowing if they can improve your production process because they are often referred to as the future of industrial automation. However, you may have also heard them described as "slow." Is that efficient enough?

For many companies, this can be a reason to doubt the effectiveness of cobots in their production processes. But is this true? Are cobots always slow?

Long story short: absolutely not. Cobots are faster and more efficient than you think. In this blog, we'll dive deeper into the myth of the slow cobot and show you why they are faster than you might expect.

Why are cobots considered slow?

The idea that cobots are slow comes from their main feature: working alongside humans. Unlike industrial robots, which often operate in isolated areas for safety reasons, cobots are designed to work in the same space as humans. For this reason, they move more slowly to prevent collisions and ensure employee safety.

Slower doesn't mean less efficient

Yes, cobots generally move slower than industrial robots, but that doesn’t mean they aren't fast enough to meet the demands of a modern production line. Thanks to technological advancements, cobots can now handle multiple products at once, significantly increasing production speed.

Modern cobots have higher payloads

Contrary to what some may think, cobots are not designed to carry heavier loads than industrial robots. However, cobots can pick up multiple products at once due to their increasing payload capacities, making them highly efficient, especially in tasks like palletizing or packaging.

Modern cobots can carry loads of up to 30 kg. Depending on the product's weight, this means they can handle multiple items simultaneously, boosting overall speed.

Cobot speed: example

Explanations are always easier with an example. Imagine you have a cobot with a 30 kg capacity and 3 kg boxes that need to be palletized.

This cobot can lift up to nine boxes at once. Even though the cobot moves slower than an industrial robot, its ability to process multiple boxes at a time compensates for this difference with efficiency.

In one movement, the cobot can move more boxes, increasing production speed and easily keeping up with your production line.

Cobot speed in practice

The use of cobots in palletizing processes is a good example of how modern cobots can work efficiently despite their slower movements. Imagine your cobot performs 8 picks per minute. With a load capacity of 30 kg, this cobot can lift nine 3 kg boxes in one go.

That means you can stack up to 72 boxes per minute—a remarkable result that, in many production environments, is more than sufficient to meet demands.

Higher payload

The core of cobot success lies not only in their speed but primarily in their ability to handle multiple products at once. This makes them ideal for various applications, from palletizing to packaging.

What if your cobot needs to be even faster?

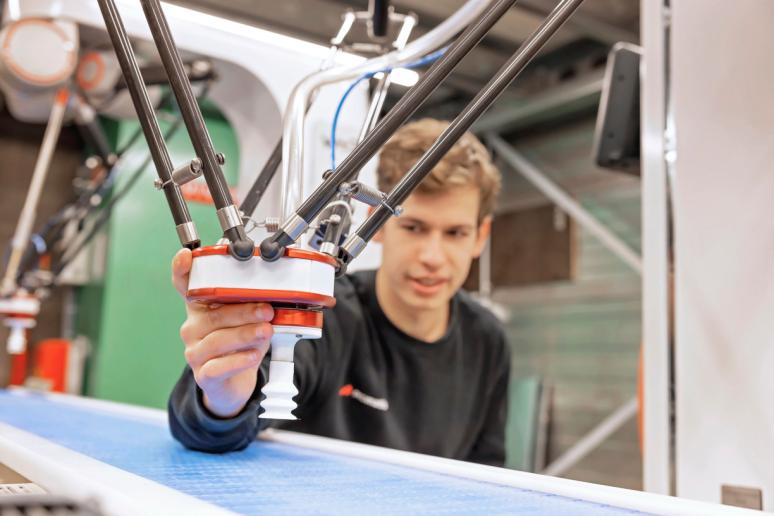

Some productions require extremely high speeds. For that, collaborative delta robots have been developed, such as Wyzo.

This delta robot can process up to 90 items per minute, which is extremely fast for a collaborative robot. It is perfect for handling smaller, lighter products (up to 1 kg each) and proves that cobots, in certain applications, can even compete with traditional industrial robots in terms of speed.

This innovation shows that cobot speeds are constantly evolving and that they are already capable of meeting very high-speed requirements.

Rules of thumb for cobot speeds: What to expect?

When considering the purchase of a cobot for your production process, it’s helpful to keep a few rules of thumb in mind. Below is an overview of typical speeds for common tasks cobots perform in a production environment. These guidelines provide insight into what you can expect from a cobot’s performance.

1. Palletizing: Up to 8 picks per minute

For palletizing tasks, the standard speed is approximately 8 picks per minute. This speed can increase if the cobot can handle multiple boxes at once. If your production process involves large volumes of boxes, the cobot can pick and stack several boxes per pick, significantly boosting stacking speed. A palletizer's speed is thus a combination of the number of picks and the number of items per pick.

Example: If the cobot picks four boxes per pick at a speed of 8 picks per minute, it can stack up to 32 boxes per minute. This approach maximizes productivity without compromising precision or safety.

2. Pick-and-Place Tasks: Approximately 4 seconds per filling movement

For pick-and-place tasks, such as filling boxes, a cobot typically requires 4 seconds to complete the filling movement. This includes picking up the product, moving it to the box, and placing it carefully inside. This 4-second rule makes it easy to estimate how many items a cobot can process per minute, depending on the conveyor belt speed and the task's complexity.

Example: Suppose a cobot transfers products from a conveyor belt to a box. With a pick-and-place cycle time of 4 seconds, it can process an average of 15 products per minute.

3. Opening Boxes: 12 to 15 seconds per box

For more complex tasks, such as opening boxes, more time is required. A cobot configured to open boxes will typically need 12 to 15 seconds per box. This is because movements must be precise and careful, especially if the box cannot be damaged. For businesses regularly handling large quantities of packaging, a cobot can be programmed to perform this task efficiently and error-free.

Example: If a cobot is programmed to open boxes and prepare them for filling, it can open an average of 4 to 5 boxes per minute. This makes it a perfect fit for a production process with a continuous flow of packaging.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Cobots are fast and efficient

We’ve successfully debunked the myth that cobots are slow. Although cobots generally move slower than industrial robots, they more than make up for this with their ability to process multiple products at once.

This boosts their efficiency, making them ideal for a wide range of applications in modern production environments.

Do you want to know which cobot suits your business best? Use our ROI configurator to calculate which cobot solution is right for you and when you'll have your investment paid back.

Don’t be fooled by the myth that cobots are slow—discover how our automation solutions can make your production faster, safer, and more efficient!