What is a Sidebot or a collaborative delta robot?

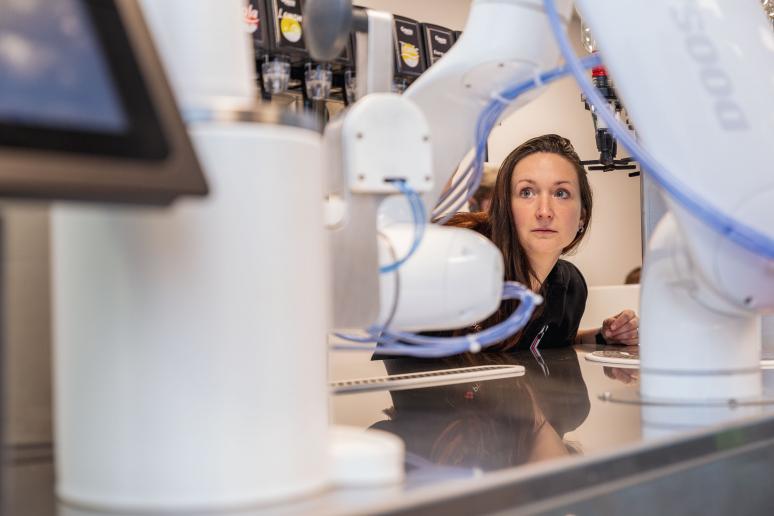

The world of industrial automation is constantly evolving. While traditional robots primarily operated in enclosed cells and cobots (collaborative robots) gradually made their way into the industry, a new player has now entered the market: the Sidebot.

A collaborative delta robot that combines the speed of a traditional delta robot with the safety and flexibility of a cobot. But is a Sidebot truly a game-changer? And is it the right choice for your production environment?

In this blog, we take a closer look at this innovative robotic technology.

What is a Sidebot?

A Sidebot is a collaborative delta robot, which means it:

- Has the typical speed and precision of a delta robot

- Can operate near humans without a safety cage

- Is flexible and mobile

- Adjusts its speed based on the presence of people

Unlike a traditional delta robot, which typically operates in an enclosed cell due to its high speeds, a Sidebot is designed to work safely alongside humans. This makes it an excellent choice for environments where human-machine collaboration is important.

How does a Sidebot work?

A Sidebot operates in much the same way as a standard delta robot. It consists of three parallelogram arms that control a central gripper, allowing it to move products quickly and precisely. The main difference lies in its safety technology and movement limitations:

- Safety features: Thanks to built-in sensors and intelligent software, the Sidebot detects the presence of people and adjusts its speed and movements accordingly. This eliminates the need for a safety cage.

- Maximum speed when no people are nearby: When no humans are detected, the Sidebot operates at full speed, similar to a standard delta robot.

- Automatic speed adjustment: As soon as a person is detected nearby via safety scanners, the robot switches to a slower, safe mode.

- Sensitive collision detection: The Sidebot uses direct drive motors with encoders instead of gearboxes. This allows the robot to sense if it collides with something and stop immediately. This is a major difference from standard delta robots, which use gearboxes and are therefore fast but "insensitive" to collisions.

Thanks to this technology, the Sidebot is the first delta robot that not only works quickly but also responds safely and intelligently to its environment.

Sidebot vs. standard delta robot: what’s the difference?

To determine when a Sidebot is the right choice, let’s compare it to a standard delta robot:

| Standard delta robot | Sidebot (Collaborative delta robot) | |

| Speed | 100+ pieces per minute | 90 pieces per minute (max) |

| Safety | Must operate in an enclosed cell | Adjusts speed based on proximity to people |

| Mobility | No, fixed in one place | Yes, easily movable |

| Available variants | Many (stainless steel, extra axes, hygienic models, etc.) | Limited, only one variant available |

| Flexibility | Low, fixed installation | High, multi-purpose |

| Collision sensitivity | Not sensitive, uses gearboxes | Sensitive, uses direct drive motors with encoders |

The key difference?

A standard delta robot is faster but requires an enclosed environment and cannot detect collisions. A Sidebot is slightly slower but offers much greater flexibility, safety, and advanced collision detection.

When should you use a Sidebot?

Sidebots are particularly suited for applications where speed and human collaboration need to go hand in hand. Some typical use cases include:

- Packaging lines: A Sidebot can be used to place products into boxes or trays without requiring major changes to the production environment.

- Food industry: Ideal for sorting and packaging food products, where fast, precise, and hygienic handling is required.

- E-commerce and logistics: Used for sorting and moving small packages or products in distribution centers.

- Assembly processes: Perfect for production lines where small components must be placed with high precision.

Example: A chocolate manufacturer wants to use a robot to place chocolates into boxes. A standard delta robot would be ideal in terms of speed, but the factory does not have space for a large safety enclosure. A Sidebot provides the perfect solution: fast enough to speed up production while being safe to work alongside operators.

The benefits of a Sidebot

Why choose a Sidebot over another solution? Here are its main advantages:

- No safety enclosure required – Works safely without fences, reducing installation costs.

- High speed – Slower than a standard delta robot but faster than most cobots.

- Easy implementation – Quick integration without major modifications to the workspace.

- Flexible deployment – Can be moved between different workstations.

- Advanced collision detection – Thanks to direct drive motors and encoders, the robot can detect collisions and stop immediately.

- Low maintenance costs – Less wear and tear due to the absence of gearboxes.

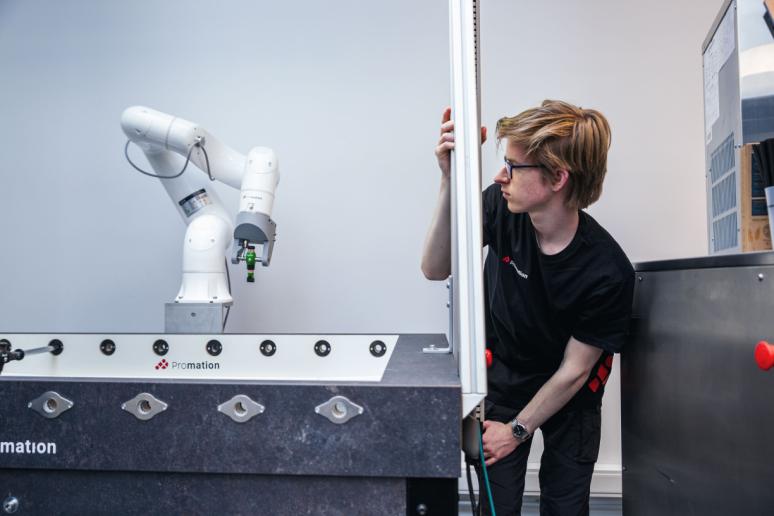

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Is a Sidebot the right choice for your business?

A Sidebot is the ideal solution for companies looking to combine speed, flexibility, and safety.