Why we only install one brand per product category

There are many brands in the automation sector. However, we strongly believe that specialization is the key to success. For us, success means combining the highest quality with the best support.

Whether it’s PLCs, vision systems, robots, or cobots like Doosan for our collaborative robots, we choose to focus on one brand per product category.

This allows us to work more efficiently, develop deeper expertise, and provide better long-term support to our customers.

While some customers sometimes ask if we can switch to other brands, we deliberately choose to say 'no.' Here’s why this is the right choice for your business.

We choose to specialize

Specialization brings many benefits, both for our customers and for ourselves. By focusing on one brand per product group, we ensure that we stay fully informed of all the nuances of those systems. This leads to:

- more efficient installations,

- shorter lead times, and

- better support.

Brands we work with

We use these brands for automation solutions:

- PLC: Siemens

- Vision systems: Cognex

- Cobots: Doosan

So, the reasons why we work with one brand and not multiple.

Reason 1: Deeper knowledge and expertise

When an integrator supports multiple brands, they need to train their employees for various systems. Whether it’s PLCs, robots, or vision systems, each brand has its unique software, programming interface, and licensing requirements.

By limiting ourselves to one brand, we can train our employees thoroughly, so they know all the ins and outs of that brand and can work more efficiently. This directly improves the quality of installation and support.

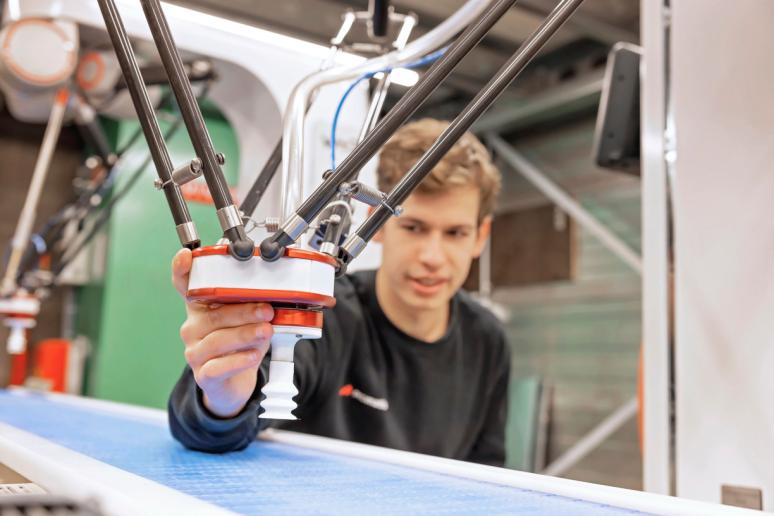

Example: Doosan Cobots

At Promation, we exclusively work with Doosan for cobots. We believe it is the best brand and aligns most with our working methods.

The choice of one brand allows us to master all the technical aspects of Doosan cobots, from installation to maintenance. When customers have a question about their cobot, we know exactly what to do because we are fully specialized in that brand.

Discover more about our cobots.

Reason 2: Faster product development and innovation

When you work with multiple brands, you constantly have to adapt your solutions to different systems. This leads to double work and slows down innovation. By focusing on one brand per product line, we can channel our energy into optimizing the systems we use.

This means we can develop and implement new solutions faster, tailored to our customers' needs.

Example: Costacker

When working on improvements for our Costacker solution, we can focus entirely on integration with Doosan cobots. We don’t have to consider other brands, allowing us to implement and optimize the solution faster.

Reason 3: Lower costs for licenses and maintenance

Working with multiple brands means purchasing licenses for each individual system. This is not only expensive, but managing all these licenses and maintenance contracts can also lead to inefficiency and higher costs.

By focusing on one brand per product category, we can save costs and pass those savings on to our customers.

Example: PLC Licenses

Using multiple brands of PLCs would involve extra costs for each brand-specific software license, as well as additional training for our team to maintain the different systems.

Reason 4: Long-term support and consistency

Perhaps the most important argument for specialization is the consistent long-term support. If a customer calls us with an issue five years later, we can immediately assist because we are fully familiar with the system installed.

This is not the case if you install various brands. Over time, you risk losing knowledge of that specific brand, especially if the employees who manage the system leave the company.

Example: Vision Systems

A customer can call us with a question about a vision system installed five years ago. Since we always work with Cognex, we have the knowledge and expertise in-house to provide immediate support without wasting time refreshing our knowledge of other systems.

Multiple brands bring multiple disadvantages

Many companies think that offering multiple brands makes them more flexible, but in practice, it causes many problems:

- Loss of consistency and potential integration issues between systems.

- Slower response times: When a problem arises with a brand that is used less frequently, it takes longer to find a solution. This can lead to production downtime and higher costs.

- Unnecessary complexity: Multiple brands require multiple licenses, maintenance contracts, and training, which increases complexity and costs unnecessarily.

We only work with 'our' brands

In the past, we have even turned down orders when customers insisted on using a brand other than our standard brand. In the short term, this may mean a loss of revenue, but we prefer to provide reliable support without complications in the long term.

That's what Promation stands for.

Allowing multiple brands would eventually lead to poorer support and an inconsistent experience for our customers.

And that’s not what Promation stands for.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

We go for long term success

At Promation, we believe that specializing in one brand per product category is the right path to sustainable and successful automation projects.

Whether it’s PLCs, vision systems, robots, or cobots, our customers benefit from our deep knowledge, the efficiency of our implementations, and the long-term support we can offer.

We choose quality over quantity, and that’s what sets us apart.