How to get started with automation and robots? Check out our step-by-step plan

Automation and robots: the secret ingredients for any modern production line. Still, we see many companies hesitate. "Is my production process suitable for automation? Isn’t it too expensive? And how can I get the most out of it?"

Automation isn’t just about replacing people; it’s about doing more with the same team. It’s a way to automate repetitive tasks and fill vacancies that are hard to staff. You know your production better than anyone, and we have the expertise in automation and robotics. Together, we create the ideal solution.

Why start with automation?

The benefits of automation are clear: greater efficiency, fewer errors, and better utilization of your current workforce. Moreover, automation helps tackle labor market challenges, such as finding staff for physically demanding or repetitive tasks.

Automation is often simpler and more cost-effective than you think. Did you know that many automation solutions pay for themselves within 1 to 2 years?

Let’s take an example:

Imagine you need to stack boxes on pallets every day. This is physically demanding work and time-consuming. With our Costacker, this task becomes fully automated. The result? Your team can focus on more strategic tasks while the robot works consistently and efficiently.

Automation isn’t a threat but a way to elevate your production process to the next level without adding extra pressure on your employees.

Follow our steps

Step 1: Analyze your production process

The first step towards automation begins with insight. Your production process is full of details you might no longer notice. That’s why it’s important to bring in an expert like us for a thorough analysis.

What do we do during such an analysis?

- Identify bottlenecks: Where are the delays in your process?

- Select tasks: Which tasks are physically demanding or repetitive?

- Define focus: Where can you achieve the most significant gains by automating certain tasks?

Real-world example:

A food company struggled to efficiently fill small meal trays. With our Cofiller, a precise filling robot, we automated the process. This allowed them to produce faster and reassign their team to other areas where human input was needed.

During the analysis, you’ll gain practical insights right away. We identify the "low-hanging fruit": processes that are quick to automate with a short payback period.

Step 2: Collaborative brainstorming

After the analysis, we’ll explore the possibilities together. This isn’t a one-way street. You know your production, and we know automation. By brainstorming together, we arrive at the best solution.

A few key questions we’ll answer together:

- Which processes should be prioritized?

- What can be automated with simple adjustments?

- How can cobots (collaborative robots) fit into your production?

Cobots: the perfect solution for getting started.

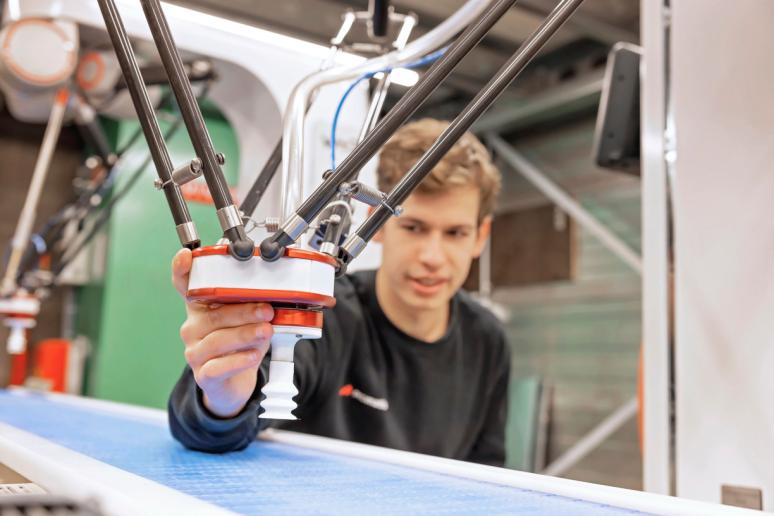

They are smaller, more affordable, and work safely alongside people. For instance, our Cofeeder ensures a continuous supply of materials to machines. Even if your space is limited, cobots can quickly deliver impressive results.

Fun fact! Our Cofeeders are so popular that we’ve even installed them in the United States. Customers appreciate their precision and ease of use.

Step 3: Proof of Concept

One of the biggest hurdles to automation is the fear that it won’t work. That’s why we often conduct a Proof of Concept for complex projects.

What does this entail?

We create a test setup that replicates the process in your factory. For example, a cobot picking up products or a vision system scanning barcodes. This lets you see firsthand that the solution works before implementing a full-scale installation.

Example:

A client wanted to automatically destack cardboard boxes, but pallets were often delivered unevenly. With our intelligent software and vision systems, we demonstrated that our cobots could handle this problem effortlessly. The client saw the results and immediately decided to expand the installation.

Step 4: From Idea to Installation

Once everything is tested, we can move on to implementation together. This includes:

- Building custom solutions, such as new control cabinets or Siemens PLCs

- Installing cobots, like the Costacker or Cofiller.

- Integrating vision systems for quality control and product recognition.

A key advantage: our flexibility. Whether you want to automate a small process or transform your entire production, we adapt to your needs.

When will you see a return on your automation?

Many companies believe automation is unaffordable, but the reality is different. Most solutions pay for themselves within 1 to 2 years. With our ROI configurator on the website, you can easily calculate which robot suits your company, the costs involved, and when you’ll recover your investment.

Example:

A client in the food industry wanted to evaluate whether a Costacker would be profitable. After using the ROI configurator, they discovered they’d recover their investment within 11 months while increasing their output by 20%.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Ready to start your automation journey?

At Promation, we believe automation is not a solo adventure. You bring your production expertise, and we provide the technology. Together, we achieve the best results.