How much does a custom cobot cost?

Many companies considering adding a cobot (collaborative robot) to their production process have questions about the costs:

- Is it an expensive investment?

- What else is involved?

- Can a cobot truly be profitable for my business?

Purchasing a cobot involves more than just the price tag. In this blog, we’ll discuss all the factors that affect the cost and debunk a few misconceptions.

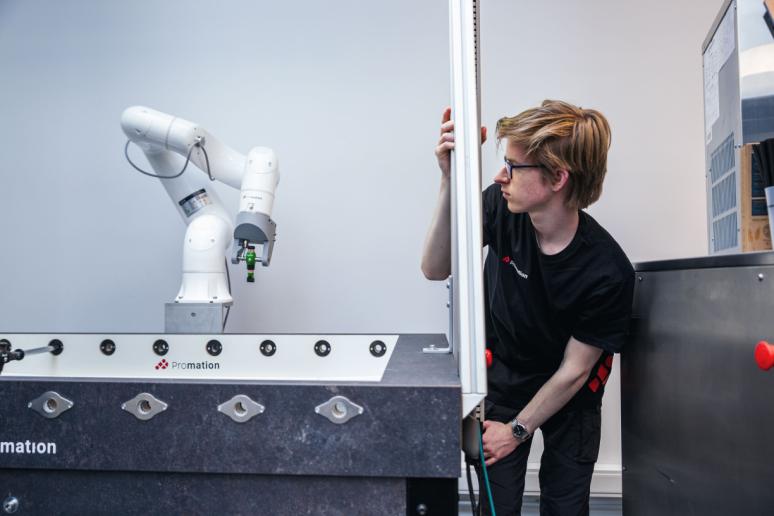

1. The cost of the cobot itself

The cost of a cobot usually ranges from €15,000 to €50,000, depending on the brand, model, and features. Some companies look for the cheapest solution, but the "best" cobot is the one that meets the specific needs of your production process. A cobot that fits perfectly reduces workload, enhances safety, and cuts labor costs, making the investment pay off quickly.

Example: Doosan P3020

For a company involved in light assembly work, a basic cobot with lower load capacity can be an efficient solution. On the other hand, a company handling heavy loads might opt for a more robust cobot with higher load capacity, like the Doosan P3020. This cobot can lift up to 30 kg and has a reach of 2 meters—ideal for heavier tasks.

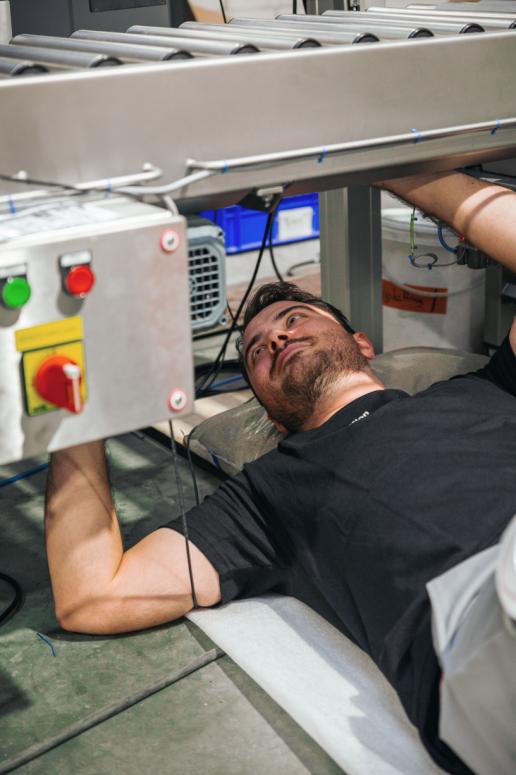

2. Installation and integration

Installing a cobot is more than just "placing and powering it on." For optimal performance, the cobot must be integrated into the production environment. This can be a straightforward setup, but complex lines may require additional modifications, such as a custom control cabinet.

At Promation, we design custom controls, enabling the cobot to work efficiently with other machines and systems in your process.

Example: Costacker

In a company stacking pallets, our Costacker can be easily installed and integrated into the existing line. However, for more complex tasks, such as filling packaging or ensuring a continuous supply of materials, additional integration work may be needed to seamlessly incorporate cobots like our Cofiller or Cofeeder into the process.

3. Training and support

Although cobots are generally easy to program, initial training is crucial to maximize their potential. At Promation, we offer training and support to ensure your employees can operate the cobot quickly and efficiently.

Example: Training for experienced teams

A team already familiar with robotics often only requires a short basic instruction. In other cases, extensive training may be needed to enable users to make small adjustments and configurations independently. This allows them to switch tasks quickly and reprogram the cobot for new activities, ultimately saving costs.

4. Load capacity and reach

Cobots come in various sizes and capacities, from lightweight models to more robust ones capable of handling heavy loads. Cobots with greater reach or higher load capacities tend to be more expensive. However, this investment can be worthwhile if your process demands higher performance.

Example: Robot vs. cobot

In a production line handling heavy materials, a cobot with higher load capacity and extended reach is essential. For lighter tasks, a cobot with lower load capacity is ideal—it’s cheaper and perfectly suited for precise, light operations such as pick-and-place tasks.

5. Number of axes on your cobot

Cobots typically have 5 or 6 axes. The more axes, the greater the range of motion. A 6-axis cobot, for example, can move in all directions, which is useful for complex tasks. A 5-axis cobot is more compact and often more affordable for simpler tasks.

When to use which cobot?

A 5-axis cobot is perfect for simple tasks like moving items along a straight line. For intricate assembly tasks requiring varied angles, a 6-axis cobot is often the better choice.

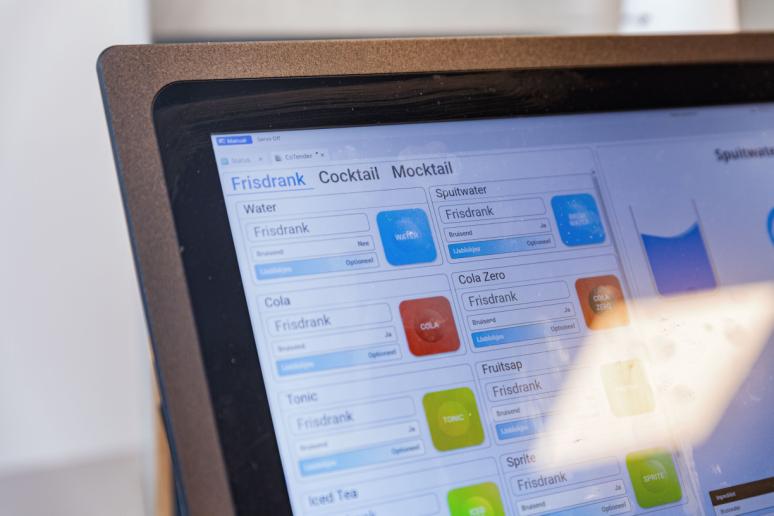

6. Accessories and tools

Depending on your processes, cobots can be equipped with various accessories, such as grippers, sensors, or cameras. At Promation, we use Cognex cameras for vision systems. These enable our cobots to inspect, locate, and perform quality checks with precision. Investment in additional tools can significantly increase cobot productivity.

Example: Vision systems

In a packaging line, a vision system can be added to scan barcodes and check printed data. This allows the cobot to perform inspections autonomously, without operator intervention. While these accessories come with additional costs, they significantly improve quality and efficiency in the long run.

7. Maintenance and service

A well-maintained cobot lasts longer and performs optimally. At Promation, we offer maintenance contracts to ensure your cobot operates seamlessly at all times. Regular maintenance prevents unexpected breakdowns and keeps the cobot running, which is critical in a continuous production line. Prevention is better than cure!

Price vs. investment

Although the total implementation costs of a cobot typically range between €30,000 and €100,000, the investment often delivers much more long-term value than just direct labor savings.

Cobots boost productivity and can be quickly deployed to different areas in production—all with a return on investment (ROI) often within a year.

ROI and payback period

Cobots often pay for themselves within a few months to a year, depending on their use and the level of efficiency they bring. Our ROI configurator, available on Promation's website, helps businesses calculate how quickly they can recover their investment.

Most companies find that cobots quickly pay off through increased production output and reduced labor costs. So there are plenty of benefits!

A cobot is affordable and customizable

Thanks to their flexibility, low maintenance costs, and rapid payback period (often within a year), cobots represent an affordable and scalable automation solution. And the best part?

We can fully customize the cobot to meet the specific needs of your business, from reach and load capacity to accessories and integration into your production process.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Curious about which cobot best suits your production environment?

Contact Promation. We’ll be happy to help you find the perfect solution for your specific needs and provide free advice.