Cobots: What factors influence their speed?

Speed and cobots—it’s a frequently recurring topic. We previously wrote an article about cobot speed. In this article, we delve deeper into the various factors that influence their speed.

The speed of a cobot impacts the productivity and efficiency of a production process, but there’s more to consider than just speed alone. Cobots must also operate safely and accurately, especially when working in close proximity to humans.

In this article, we explain how a cobot’s speed is determined, which factors influence it, and the general guidelines you can follow for specific tasks.

Balancing safety, task, and model

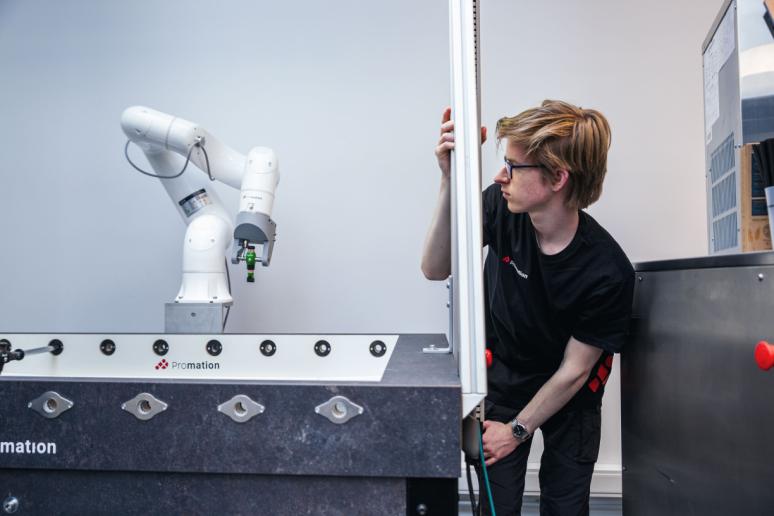

Cobots are designed to work safely and efficiently alongside humans. This means their speed is often lower than that of traditional industrial robots operating in safety cages.

A cobot’s speed typically ranges between 250 mm/s and 1,000 mm/s, depending on the model, the task, and the safety settings. For every task, cobots are programmed to strike a balance between speed, accuracy, and safety.

1. Safety is always the top priority

Safety is critical in the operation of a cobot. Since cobots don’t require cages and can work directly alongside people, they must meet strict safety standards. This means their speed is automatically reduced when they are near humans.

If someone approaches too closely, the cobot can immediately slow down or even stop. This ensures safety but also means that speed can vary depending on the situation.

Learn more about cobot safety

2. The task assigned to the cobot

A cobot’s speed is often adjusted based on the complexity and precision of the task. For simple pick-and-place tasks, the cobot can operate faster than for tasks requiring high precision, such as opening a box or stacking fragile items.

For example, a palletizer can work at high speed, especially when it can pick up multiple items at once.

3. The cobot model

Different models of cobots come with varying speeds and capabilities. At Promation, for instance, we use Doosan cobots that offer a wide range of speeds and precision levels. By selecting the right cobot for a specific task, you can optimize the speed and efficiency of your production process.

Factors influencing cobot speed

Beyond general guidelines for specific tasks, other variables affect the speed at which a cobot can operate:

1. The weight of the product

Cobots are designed to handle various weights, but heavier objects often require slower speeds. For instance, if a cobot is stacking boxes weighing 20 kg each, it will likely operate more slowly than when handling lighter objects.

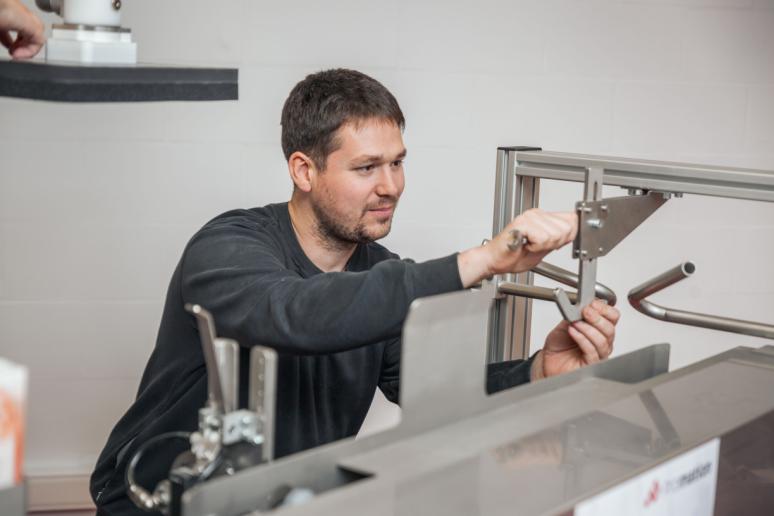

For heavy tasks such as palletizing, a stronger and more stable cobot, like our Costacker, is ideal as it is designed to stack safely and efficiently without compromising speed.

2. Precision requirements

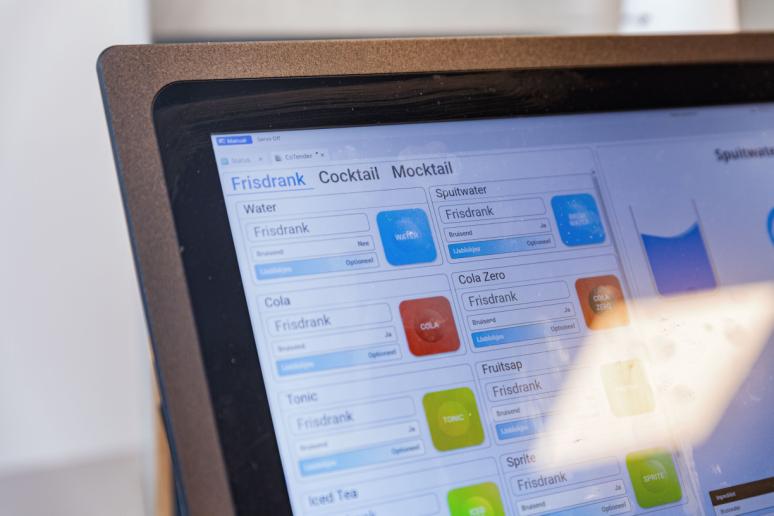

Tasks requiring higher precision are generally performed at slower speeds. For example, when a cobot needs to execute millimeter-perfect actions—such as filling packaging or placing components—its speed is adjusted to avoid errors. This increases the reliability of the process but slightly reduces the speed.

3. The automation level of the workspace

A cobot’s speed can also be influenced by the overall level of automation in the workspace. When a cobot is part of a fully automated process, it can often operate faster because all other machines are synchronized. In a hybrid environment where humans and cobots work alongside each other, the cobot may automatically slow down to ensure safety.

Choosing between speed and balance

While speed is important for productivity, it is crucial to find a balance between speed, safety, and accuracy. Cobots are designed to perform efficient, repeatable actions, making them ideal for businesses looking to optimize their production processes without compromising safety.

By adjusting speed to match the task and environment requirements, a cobot can work consistently and reliably, enhancing both production quality and efficiency.

Speed guidelines

The speed of a cobot can vary significantly depending on the task and model. For simple tasks such as pick-and-place, a cobot can complete a filling motion in 4 seconds, while opening a box might take 12 to 15 seconds. For companies needing efficient palletizing, speeds can reach up to 8 picks per minute—with the potential to handle multiple boxes per pick.

Learn more about our cobot speeds

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Cobots: The perfect balance

Cobots offer the ideal balance between speed, safety, and precision, making them a valuable investment for companies looking to remain flexible and efficient.

Are you curious to learn how a cobot could impact the speed of your production process? We’re happy to help you find the right cobot and determine the optimal speed for your applications.