Does a cobot need fencing and scanners or not?

Cobots are often praised as robots that don't require fencing or scanners. They are safe, flexible, and designed to work side by side with people without physical barriers. But is this true in every situation?

The idea that cobots can always operate without fencing is appealing, but in practice, it’s often a bit more complicated. Depending on the application and environment, additional safety measures may be required to ensure both efficiency and safety.

In this article, we’ll dive into the details of when cobots can and cannot operate without fencing. We’ll explain when scanners or small barriers might be needed and how cobots can still maintain their unique benefits even in fully enclosed environments.

Cobots: Collaborating without barriers?

One of the greatest advantages of cobots is their ability to work safely alongside humans. Thanks to built-in safety sensors, cobots can detect collisions and automatically stop if they come into contact with a person.

This makes them ideal for production lines where people work in close proximity to the cobot, especially when no heavy or dangerous objects are being handled.

Learn more about cobot safety.

Task and environment

This safety largely depends on the task and the environment in which the cobot operates. For example, if a cobot uses a standard gripper in a quiet area with little traffic, additional fencing or scanners are often unnecessary.

In such cases, the cobot can collaborate seamlessly with people without requiring extra safety measures.

Safety scanners

The need for fencing or safety scanners arises when a cobot uses a more hazardous gripper or operates in a busy environment.

For instance, if a cobot handles a sharp, heavy, or otherwise dangerous gripper, installing safety scanners is often mandatory. These scanners detect when someone approaches the cobot and ensure that it slows down or stops to prevent accidents.

Safety vs. efficiency

The downside of scanners in busy environments is that they can reduce productivity. If the cobot is located in an area with heavy foot traffic, such as a corridor or a busy workspace, it will constantly have to stop or slow down whenever someone comes too close. This disrupts the production process and may prevent you from achieving desired production speeds.

Solution: Limited barriers

Instead of fully enclosing the cobot, a limited barrier can suffice to keep the cobot's operating area safe.

This way, the cobot doesn’t have to stop every time someone comes near, allowing it to continue working at full speed. Such fencing is often small and localized, placed close to the cobot, and provides just the right amount of protection without compromising the cobot's flexibility.

Example: Fencing for our Costacker

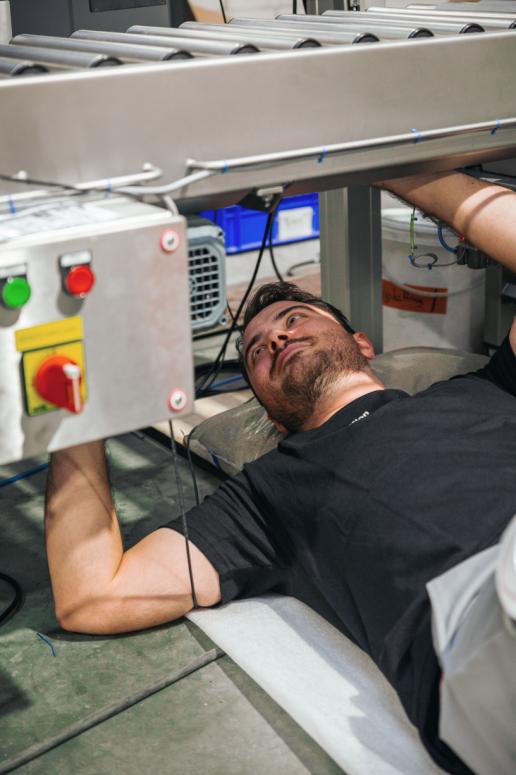

Let’s put this into perspective with an example. Our Costacker, a cobot designed to efficiently stack boxes onto pallets, works safely alongside people thanks to its built-in sensors.

However, if the Costacker is placed next to a busy walkway, it may constantly have to stop due to scanners detecting every movement nearby. By placing a small piece of fencing next to the cobot, it can operate uninterrupted without being hindered by passing workers.

This small barrier ensures that the cobot maintains safety while working efficiently, without having to frequently slow down or stop due to nearby movements. It’s a smart way to maintain production speed without compromising safety.

When should you fully enclose a cobot?

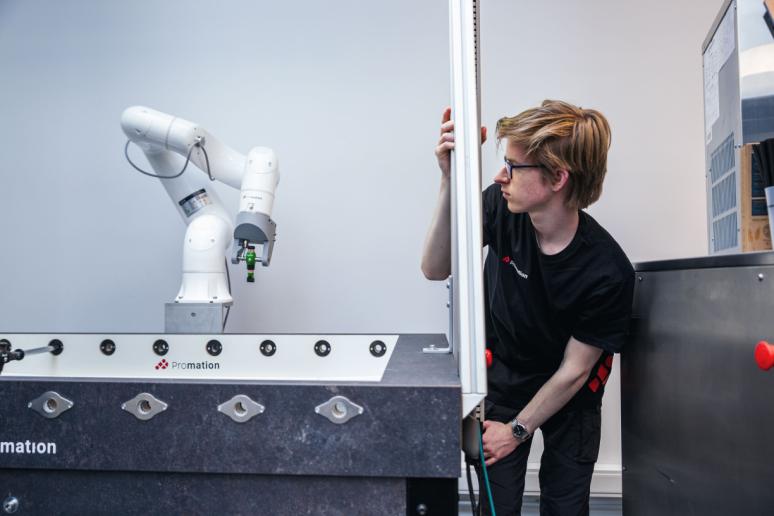

There are situations where a cobot needs to operate in a fully enclosed space. This is usually the case when working with particularly fragile or expensive products, such as glass or sensitive electronics.

Even in these cases, cobots remain the best choice despite the enclosure. This is because cobots are designed to work with “sensitivity” – they can handle delicate objects without causing damage.

A cobot is smaller than a robot

Cobots are also much more compact than traditional industrial robots, meaning they are easier to integrate into smaller spaces. Even in a fully enclosed application, the compact size of a cobot allows for more efficient use of space and a smaller footprint.

This is one of the reasons cobots remain popular in closed systems: they offer both safety and space-saving benefits without sacrificing precision or sensitivity.

Example: Handling fragile objects

An example of this is an application where a cobot processes delicate, fragile objects. While the cobot may need to be fully enclosed to protect workers from potential collisions, it remains the ideal choice due to its ability to handle fragile products with care.

Traditional robots are often too large and not refined enough for such tasks, whereas a cobot’s precision and sensitivity allow it to perform the job without causing damage.

Why choose a cobot anyway?

If a cobot sometimes needs to operate within an enclosure, why not just choose a traditional robot? The answer lies in the unique advantages cobots offer. Even in enclosed environments, a cobot’s compactness and precision remain key benefits.

Cobots are:

- Smaller,

- More flexible,

- And better suited for tasks requiring sensitivity, such as working with delicate materials.

Additionally, cobots, with their built-in safety features, are often easier to program for sensitive tasks than traditional robots. Where a traditional robot might need additional sensors and more complex grippers to safely handle fragile objects, a cobot can naturally perform these tasks thanks to its advanced sensors and “sensitive” movements.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Conclusion: Cobots are safe, but fencing is sometimes necessary

In situations where dangerous grippers are used or where many people work near the cobot, scanners or small barriers may be essential to ensure both safety and efficiency. However, this doesn’t mean the benefits of cobots are lost.

Cobots remain more compact, precise, and sensitive than traditional robots, making them ideal for a wide range of applications – even in enclosed environments.

At Promation, we specialize in delivering customized automation solutions. Our cobots, such as the Costacker and Cofeeder, are designed to operate safely and efficiently, whether in an open workspace or behind a barrier.