Automation in the corrugated industry: Efficiency and innovation in every process

In the corrugated industry, everything is about speed and flexibility. From feeding cardboard to stacking heavy boxes, many processes are still manual. This not only leads to high labor costs, but also inefficiency and a greater chance of errors.

That’s why automation has a huge impact on this sector. Whether it’s automating cardboard feeding, stacking boxes, or upgrading machines like folder-gluers, our solutions are designed to inspire and perform.

Read our blog to discover how automation can transform your corrugated processes.

Why automate in the corrugated industry?

The corrugated industry faces specific challenges such as heavy physical labor, strict precision requirements, and high volumes. Automation helps overcome these challenges and makes processes both more efficient and reliable.

- Reduces manual labor: Let robots and cobots handle tasks like feeding cardboard and stacking boxes.

- Increases efficiency: Automation ensures higher output with less downtime.

- Flexibility: Cobots and robots can easily be adapted to various product sizes and weights.

- Upgrade of existing machines: By applying retrofits to existing folder-gluers, you make them ready for the future.

Looking for subsidies for your automation processes? Read more in our blog!

The biggest opportunities for automation in the corrugated industry

Automation can be applied to almost any process, but cardboard feeding, box stacking, and machine upgrades offer the most opportunities.

Automating cardboard feeding

Manually feeding cardboard into machines is labor-intensive and error prone. With a solution like the Cofeeder, you fully automate this process.

Example:

A customer in the corrugated industry used our Cofeeder to feed cardboard into a carton machine. The result? Less downtime and significantly higher efficiency.

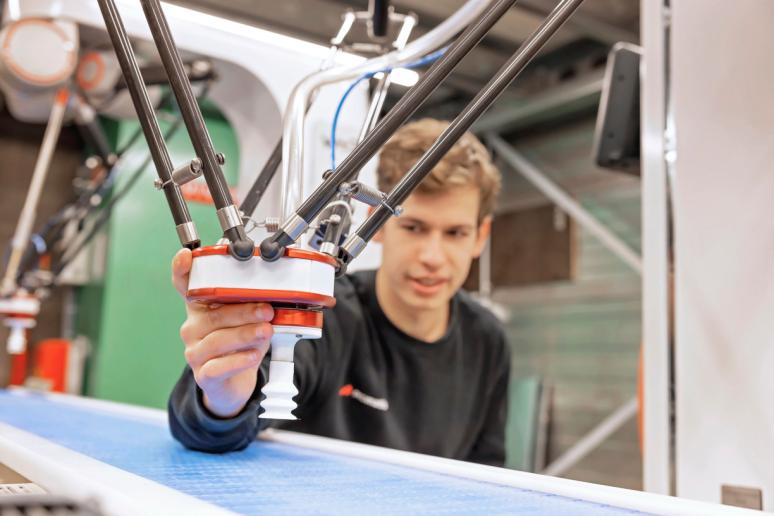

Stacking boxes with robots and cobots

Stacking boxes is physically demanding work, especially as the weight increases. Cobots are ideal for lighter tasks in compact spaces, while industrial robots are suitable for stacking heavier boxes.

Example:

At one customer site, we implemented a Costacker to automatically stack boxes onto pallets. For heavier boxes, we used an industrial robotic arm. The process is now fully automated, with less physical strain on employees.

Retrofit of folder-gluer machines

Folder-gluer machines are crucial in the corrugated industry, but many machines have outdated controls and limited capabilities. With a retrofit, you can upgrade these machines and make them more efficient.

Example:

A customer had an outdated folder-gluer that had to be operated manually. By integrating a new Siemens control system and partially automating the process, boxes were folded and glued faster and more consistently.

Flexibility with cobots

Cobots are compact, safe, and flexible. They can easily be adapted to various tasks, such as stacking boxes, feeding cardboard, or supporting operators.

Example:

At one customer site, a cobot was used for both cardboard feeding and box stacking. Thanks to simple reprogramming, the cobot could quickly switch between tasks depending on production needs.

Why choose Promation?

At Promation, we offer both standard solutions and custom designs. Our clients appreciate our creativity and experience, allowing us to automate even the most complex processes.

What our clients say:

"Promation gave our production a huge boost through a combination of standard solutions and custom designs. Their retrofit solutions gave new life to our old machines."

Our expertise includes:

- Automating cardboard feeding with systems like the Cofeeder.

- Stacking boxes with cobots and industrial robots.

- Retrofits for folder-gluer machines, including new controls and improved processes.

How to get started with automation?

Many companies in the corrugated industry don’t know where to begin. Our tip: Start with processes that offer quick returns, like cardboard feeding or box stacking.

At Promation, we offer a free analysis to identify opportunities in your production process. With our ROI configurator, you can instantly calculate which automation solution fits your business and how quickly your investment will pay off.

Written by Stijn Provoost

Founder of Promation. Passionate about programming and new technologies. With Promation, Stijn has one major goal: to improve production processes through industrial automation, robotics, and vision systems.

Automation in the corrugated industry is important

Automation provides solutions to the key challenges in the corrugated industry: labor-intensive processes, physical strain, and inefficiencies. Whether it's cardboard feeding, box stacking, or upgrading existing machines, Promation has the expertise to optimize your processes.