5 common mistakes when buying a machine

Purchasing your new machine isn't something you do overnight. And yet we often read that companies are disappointed after delivery of their newest flagship. After all, the machine turns out not to be so user-friendly or does not meet expectations. We list 5 common mistakes for you. So you can avoid a cold shower on your next purchase.

1. No clear purpose

2. Not tested

3. Forgotten counting

4. Faulty components

5. Price over service

No clear purpose

In all your enthusiasm, you request quotes from different suppliers. Since you have been working with them for years, you assume that they know your methods and requirements. Attention: what is obvious to you and your operators is not to others. You work with the machines every day and know all the pros & cons. It is important that you share all the details with the machine builder. Take the time to set clear goals together and list all the features of the machine in a specification book. Such a specification book gives the machine builder a handhold in the design and construction, so you avoid mistakes and discussions. This way, you get the machine or robot that boosts your production. Win-win.

Not tested

Handsome design ... on paper. Is it in reality? Does the machine effectively do what the representative claims it can do? There is only one way to find out. Extensive testing. Dare to ask the supplier. You both benefit from a well-functioning machine or robot. Perhaps a colleague in another region invested in the same machine and you can see it in operation there. Definitely worth a visit.

Forgotten counting

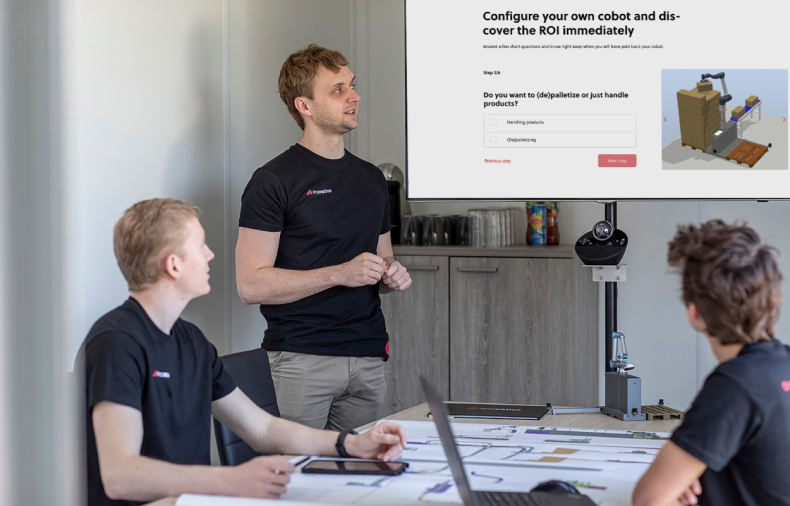

"Nice design, sure, but uh, what does that slide?" Because a new machine or robot has to pay for itself, of course. By making a good calculation of the ROI (return on investment) in advance, you will know what the machine can effectively bring in for your business and whether it is worth the investment.

Faulty components

Machine purchased. Check. It doesn't stop there, however. You obviously want your new machine or robot to last as long as possible. And preferably without downtime. Because downtime costs money. You do that by investing in the right components from day 1. Quality over quantity. The right control, the appropriate software and correct components are worth their weight in gold. What use is a cheap, exotic PLC that fails every month and on which only a few expensive technicians can work... Better to choose A-brands with local, reliable suppliers who have common spare parts in stock. They often depanel you à la minute. Service assured and financial hangover avoided.

Price over service

Our final point ties in seamlessly with the above. All too often the price tag is placed above service. And we're not just talking about delivery and accompanying training of your employees. Excellent after-sales service is also an added value. Efficient resolution of errors and accessibility outside office hours are just a few things that make the difference. That extra s(mile), that's where we come in, from Promation. We are more than a supplier. We are your reliable partner when it comes to machines and robots.